Digitalization for Electrical Asset

Precision Data for Electrical Maintenance

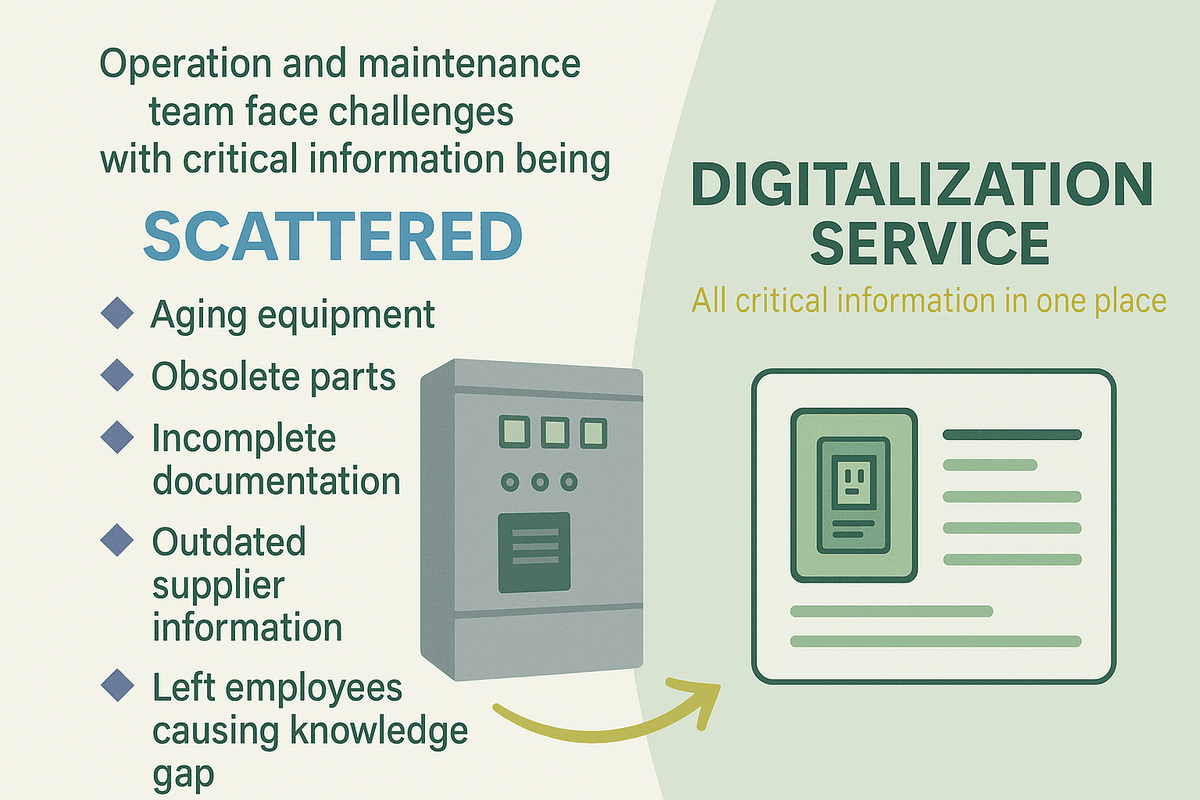

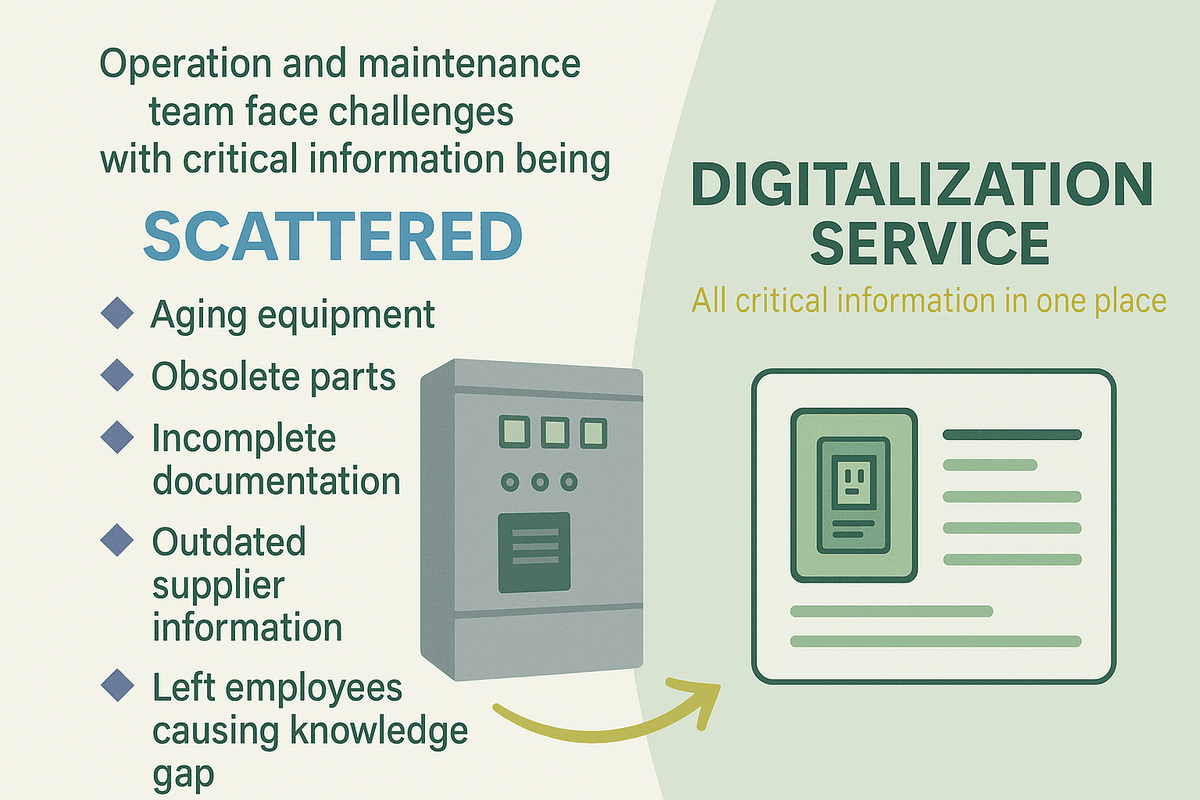

Key Value

Scattered, outdated equipment data slows down maintenance and increases downtime. Our digitalization service solves this by consolidating all critical information—equipment records, parts specs, supplier contacts, and documentation—into a single, accessible digital platform. Designed for plant and O&M managers, it eliminates knowledge gaps, streamlines workflows, and supports smarter, faster maintenance decisions that keep your operations running smoothly.

How Do We Do

Managing physical assets has always been a fragmented, time-consuming process.

We’ve reimagined this challenge and developed a smarter, faster, and more accurate way to

Document, Manage, and Maintain your Electrical Assets.

Survey & Onboard

Our process starts with an on-site survey, where our team works closely with stakeholders to:

- Identify key equipment, systems, and infrastructure to be documented

- Understand existing pain points, such as incomplete records, outdated drawings, or maintenance gaps

- Assess the physical layout, safety considerations, and documentation priorities

- Review existing materials (e.g., spreadsheets, manuals, drawings) for integration or digitization

- Onboard customer with initial proposal, based on points of equipment

Data Collection

Our standardized operation procedure enhanced with inhouse tool allows field personnel to capture high-resolution photos of assets, components, and equipment on-site, with:

- Timestamped and geotagged

- Linked to asset IDs or QR/barcode labels

- Annotated with text notes

- Tagged with condition, status, and location

Data Process

All field data, media files, and drawing annotations are consolidated into a centralized and standardized digital asset register.

- Organizes assets by category, location, and type

- Auto-fills metadata using templates for components, models, and suppliers

- Flags inconsistencies, duplicates, or missing information

Data Publish

The finalized data is delivered through a secure cloud-based portal, giving stakeholders real-time access to:

- Asset records and photos

- Maintenance logs and inspection schedules

- Spare parts and supplier references

- Exportable reports in PDF

Free Site Survey

Book today to arrange a free site survey with no obligation, to review site condition, to understand your stree and pain points.

Pain Points We Address

Main pain points that are troubling our prospect customers!

Outdated Documentation

Paper records, fragmented spreadsheets, and legacy drawings make it hard to track what's actually installed on-site.

Poor Visibility

Teams often lack real-time insight into equipment condition, leading to reactive rather than proactive maintenance.

Inefficient Maintenance

Technicians waste time identifying components or locating technical documents, especially during downtime.

Free Digitalization Package

Still not sure?

We could offer you a free digitalization package for 2 points of device, worth S$200!

No obligation!

Benefits We Deliver

Key benefits we bring to customer for pain relieve!

Digital Asset Register

All your equipment data, drawings, and photos—structured, searchable, and accessible from a single cloud platform.

Better Decision-Making

Up-to-date records support smarter planning for upgrades, replacements, and procurement.

Faster Maintenance

With visual asset identification and linked documentation, technicians and engineers save hours on every task.

Count on us to Deliver

- We Make it Effortless for you!

Professional Team with decades of experience

Free Onsite Survey to best suit your specific requirements

Standardized Operation Procedure for fast execution with minimal disruption to your operation.

We handle everything from onsite data collection to data processing from back office, so your team can stay focused while we deliver clean, accurate results, ready for digital integration.

info@

baoservice.net

+65 8511 9195

10 Bukit Batok Cre.

Reach out to Us

Share with us your request, and we will reach to you at the soonest!

Name *Email *Phone *Message *

Name *Email *Phone *Message *

© 2025 Bao Service